In general, they are old floor slabs which need restoration and consist of a bearing structure made of beams with wooden boards on top. This type of floor slab is in most cases too light and is affected by both airborne noise and footstep noise. Also very often, it is not completely continuous and noise can also pass through holes, cracks and porosity. In this case it is not possible to refer to the law of mass and it is better to ask for the advice of a noise expert, who will reconcile different needs, considering that acoustic insulation solutions often contrast with customers' aesthetic needs and they get upset if the technician proposes a false ceiling or panels hiding the beams. Another complication regarding footstep noise is that both the insulating materials of floating floors and resilient floors do not have the same performance as cementitious floor slabs, that are heavy and stiff with substantial differences of ?Lw of 10-20 dB. The problem arises particularly at low frequencies, where the light and elastic wooden floor slab (where no structural consolidation is required), has a big acoustic defect in a frequency range where insulating materials are not very effective. The guidelines for wooden floor slab insulation can be summarised in:

• ensuring air tightness of the floor slab. Materials such as TOPSILENTBitex and TOPSILENTDuo can perform this function

• increasing as much as possible the mass and rigidity of the floor slab.

When a false ceiling can be made, it should have the best possible performance, with the space insulated with mineral or synthetic wool and with the hung infill element consisting of several layers of covered plasterboard, preferably sandwich type with sound-resistant TOPSILENTBitex foil. This solution will also undoubtedly provide good insulation from airborne noise.

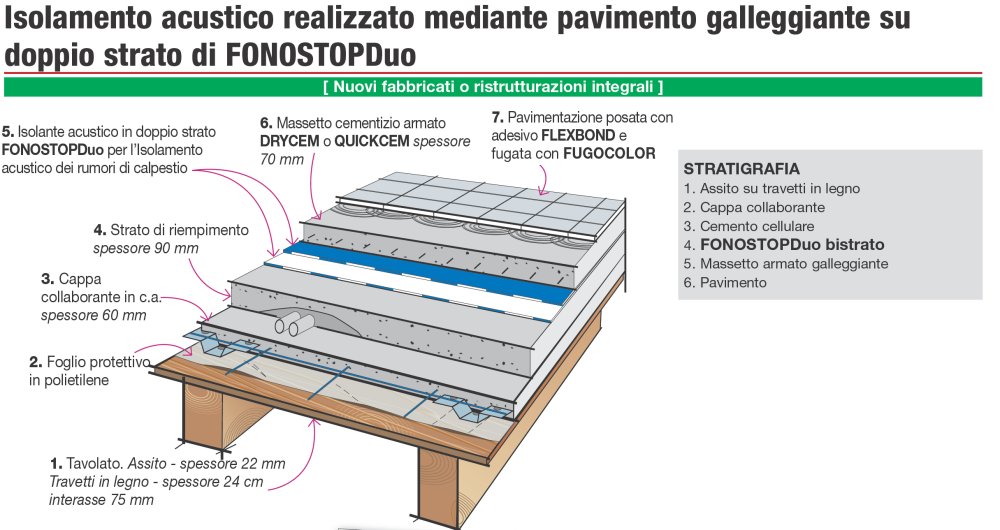

Below, there is a stratigraphic representation of a wooden floor slab with the B solution insulation, FONOSTOPDuo laid in double layer and opposing faces which has been measured in operation obtaining an L’n,w of 58 dB.

Description of the layers and related product data sheets:

INDEXTENE HDPE SUPER

QUICKTERM

FONOSTOPDuo

FONOSTOPDuo

FONOCELL - ROLL - ANGLE

DRYCEM PRONTO

QUICKCEM PRONTO

QUICKCEM PRONTO HP

FLEXBOND

GENIUSTRONG

FUGOCOLOR 0-4

FUGOCOLOR 2-12

FUGOCOLOR 4-15

FUGOCOLOR MAXI

FUGOPOX AB

FUGOPOX COLOR AB

For proposals or different solutions please contact our technical department of Index S.p.A.

GUIDE TO ACOUSTIC INSULATION FOR BUILDINGS

GUIDE TO ACOUSTIC INSULATION FOR BUILDINGS