1. Completely remove all traces of flaking concrete and dirt by high-pressure water washing;

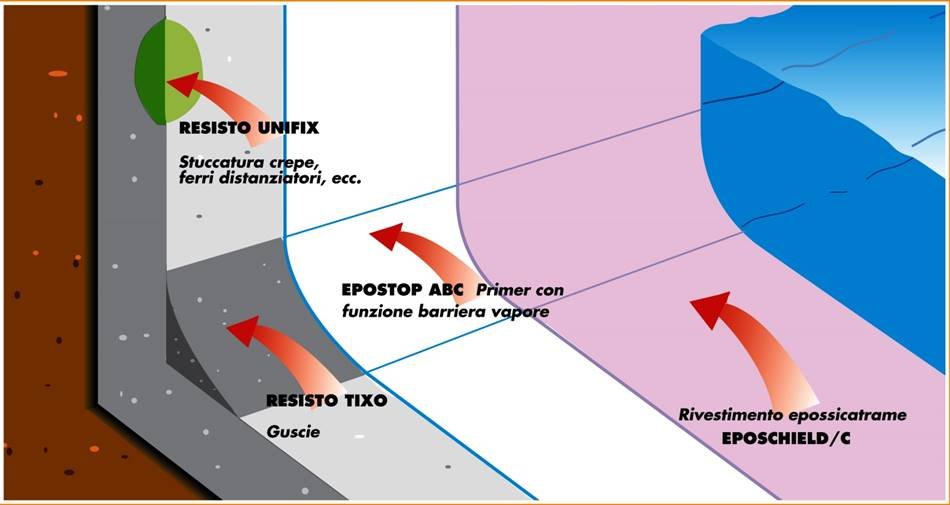

2. Open and fill the concrete joints, gravel nests and the chipped parts with compensated shrinkage high-strength cement-based mortar with extra-adhesion, selected aggregates with a maximum grain size of 0.6 mm and additives that guarantee excellent workability, thixotropy for applications up to 2 cm without the use of formwork and using RESISTO UNIFIX.

3. Make rounded edges between wall and floor (if not already existing) 5´5 cm, recessed about 2 cm using a fibre-reinforced high-strength concrete-based mortar with compensated shrinkage, selected aggregates, synthetic fibres and additives which guarantee excellent workability, adhesion, thixotropy for applications with thicknesses of 4-5 cm without the use of formwork and using RESISTO TIXO.

4. Apply a coat of anchoring agent and primer acting as vapour barrier EPOSTOP ABC in order to make a waterproofing coating on concrete surfaces, grouts and smoothing works. EPOSTOP ABC also adheres to highly-smooth and not fully hardened concrete surfaces, or to damp surfaces; minimum consumption 700g/m2

5. Apply a protection coat against chemical aggression containing epoxy-polyamide resin modified with super-dry selected tar pitch hardened at ambient temperature by using EPOSHIELD/C; apply 2 coats of the product with a minimum consumption of 300/350 g/m2 per coat

Description of the layers and related product data sheets:

RESISTO UNIFIX

RESISTO TIXO

GEORAPID

EPOSTOP ABC

EPOSCHIELD/C

For proposals or different solutions please contact our technical department of Index S.p.A.